What is stainless steel wire mesh and its uses?

stainless steel wire mesh is a versatile material used across various industries. According to a recent market analysis, the global stainless steel mesh market is expected to grow by 4.5% annually from 2022 to 2028. This growth highlights its importance in construction, filtration, and food processing.

Its unique properties, such as resistance to corrosion and high tensile strength, make stainless steel wire mesh a preferred choice. In construction, it is often used for reinforcing concrete and providing stability. In filtration, it effectively separates particles and improves quality. Food processing industries utilize it for hygienic purposes.

However, not all applications leverage its full potential. Some industries still rely on inferior materials, missing out on the benefits of stainless steel wire mesh. This presents an opportunity for improvement. Understanding its uses can lead to better decisions and innovations. Enhanced usage could transform operations in many sectors.

Definition of Stainless Steel Wire Mesh

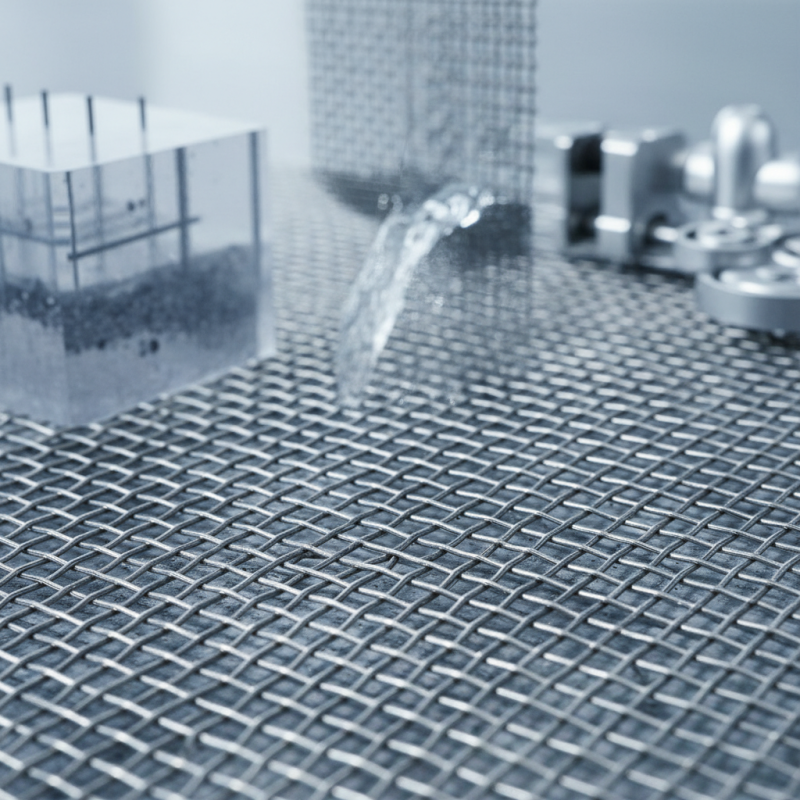

Stainless steel wire mesh is a versatile material used in many industries. It consists of interwoven stainless steel wires, creating a strong and durable mesh structure. The wires are resistant to corrosion, which makes them ideal for various applications, including filtration and safety barriers. According to a market research report by Smithers Pira, the stainless steel mesh market is projected to grow steadily, driven by increased demand in the construction and manufacturing sectors.

The definition of stainless steel wire mesh can be summarized in its unique composition and properties. Typically, it contains between 10.5% to 30% chromium. This addition increases its resistance to rust and oxidation. The mesh is measured in terms of openings per linear inch. More openings mean finer filtration. Various grades of stainless steel exist, each suited for specific applications and environments. For instance, 304 stainless steel is commonly used in food processing. However, its protection against higher temperatures is limited.

Despite its advantages, stainless steel wire mesh presents challenges. For instance, precision in production is essential, but variations can occur. These inconsistencies impact filtration efficiency. Additionally, high costs can deter smaller businesses from using it. Sustainability is another concern. While stainless steel is recyclable, the initial production is energy-intensive. Balancing performance and environmental impact remains a critical discussion in the industry.

Composition and Types of Stainless Steel Wire Mesh

Stainless steel wire mesh is made from a blend of steel and chromium. This composition gives it corrosion resistance. The steel varies in content, influencing strength and durability. Common types include welded, woven, and expanded meshes. Each type has unique applications and characteristics.

Welded wire mesh offers structural strength. It’s often used in building and construction.

Woven wire mesh, on the other hand, provides flexibility. It is ideal for filtration and separation tasks.

Expanded metal mesh consists of sheets that have been cut and stretched. This type is lightweight and strong, suitable for various industrial uses.

Tips: Always consider the environment of use. Will the mesh face exposure to harsh elements? Choosing the right type is crucial. Review specifications carefully; they affect the mesh’s longevity. Regular maintenance can enhance the mesh's performance. Pay attention to any signs of wear. This can prevent failure in critical applications.

Common Applications of Stainless Steel Wire Mesh

Stainless steel wire mesh is versatile and widely used in various industries. Its durability makes it ideal for both industrial and domestic applications. One common use is in filtration systems. The mesh effectively captures particles and contaminants. This is particularly important in water treatment plants. There, the mesh ensures clean water for communities.

Another significant application is in architecture and construction. Stainless steel wire mesh supports decorative elements. It can be used as partitions or facades. Its strength provides structural safety while enhancing aesthetics. Additionally, it serves as a safety barrier in railings and balconies. This ensures that people are kept safe from falls.

Agriculture also benefits from stainless steel wire mesh. Farmers use it for animal enclosures and crop protection. It keeps pests away without harming them. However, it is crucial to maintain the mesh over time. Neglect can lead to rust and diminished effectiveness. Regular inspections are necessary to ensure durability and functionality.

Advantages of Using Stainless Steel Wire Mesh

Stainless steel wire mesh is durable and versatile. It's made of interwoven stainless steel wires, creating a grid-like structure. This material is excellent for various applications, from filtration to architectural design.

One of the main advantages is its resistance to corrosion. Unlike other metals, stainless steel doesn't rust easily. This makes it ideal for outdoor use. It can withstand harsh weather without deteriorating. The mesh is also non-reactive, so it won't affect food or other materials.

Tips: When choosing stainless steel wire mesh, consider the gauge and weave style that best fits your needs. Different applications may require varied specifications. Also, ensure that the mesh is properly installed. A poor installation can lead to weak spots.

Another advantage is its strength. Stainless steel wire mesh offers high tensile strength. It can bear heavy loads without deforming. This feature makes it suitable for industrial applications. It’s also easy to clean, ensuring hygiene in environments like kitchens or laboratories.

However, procuring the right size can be challenging. Sometimes, you'll need to customize the mesh for specific projects. This can increase costs and lead times, but the benefits often outweigh these drawbacks. Balancing quality with practicality is key.

Maintenance and Care for Stainless Steel Wire Mesh

Stainless steel wire mesh is known for its durability and corrosion resistance. However, proper maintenance is key to prolonging its life. Regular cleaning can prevent the buildup of dirt and contaminants. A simple solution of warm water and mild soap works wonders. Avoid harsh chemicals, as they can damage the surface. Experts recommend cleaning stainless steel wire mesh every few months, especially in harsh environments.

Inspecting the mesh for physical damage is vital. Look for rust spots or any signs of wear. Routine checks can help identify issues before they become serious. According to industry reports, neglecting maintenance can reduce the material's strength by up to 40% over time. The presence of moisture can exacerbate these issues. Drying the mesh after cleaning is essential to avoid rust formation.

Stainless steel wire mesh can be a long-term investment. But it requires effort to maintain its appearance and functionality. Some users may overlook minor damages, assuming they will not worsen. Yet, small problems can lead to bigger failures. Staying proactive in care will ultimately yield better performance.